What is Enamelling?

Enamelling is the art of applying richly coloured powdered glass to the surface of metal and firing it at high temperatures to create a glorious permanently coloured surface glaze/pattern.

This method of using glass to enamel with is known as Vitreous Enamelling, and it has been a technique used for Centuries to apply colour to fine jewellery and precious objects.

IMPORTANT NOTE: Cold Enamel is the use of two part resin to create colour, this material is NOT traditional vitreous fired enamelling.

Enamelling Techniques | The Big 4

- A brief explanation of the most well known Enamelling Techniques

What is Cloisonné Enamelling?

The Cloisonne technique requires the fusing of a decorative pattern of very fine wire cells onto the surface area of the metal during the first stage of the enamelling application process.

These wire compartments are evenly filled or inlayed with various colours of vitreous enamel paste and fired in a kiln.

Once fired, the piece is carefully finished by grounding the surface of the enamel with an Alundum stone, until the top of the retaining wires are visible, this often requires a repeat of the grinding, filling and firing processes several times.

Once the item is finished, the wires should be visible and integral to the overall design, therefore for this method the enameller must be very precise when attaching the wire cells and during the finishing process.

What is Champleve Enamelling?

A similar technique to Cloisonne, however instead of adding departmental wires to hold the enamel, Champleve is the art of creating a design comprising of channels or grooves created by removing metal from the surface of the metal. A high level of skill is required to produce a refined finish when creating the cavities.

Metal can be removed using techniques such as engraving, etching or a piece can be pre-cast with cavities included.

The cavities created are then filled with vitreous enamel and fired until the enamel fuses. The surface is then finely sanded down to create a smooth finish.

A Champleve enamel design is traditionally is a combination of a plain and enamelled surface area and it is a technique often used to cover larger objects.

What is Plique-a-Jour Enamelling?

This very challenging technique requires either open wire decorative cells to be created or finely saw pierced items to be infilled with vitreous enamel.

Because the wirework cells or pieced work have no back the finished result is similar to a fine stained glass window, in which light passing through enhances the original design.

A glutinious enamel paste is applied to the open frame work created, relying on a very steady hand and capillary action to hold the enamel in place, sometimes a temporary backing can be applied which is removed after the piece is fired in the kiln.

Adding the enamel and careful firing are repeated many times until the final design is completed.

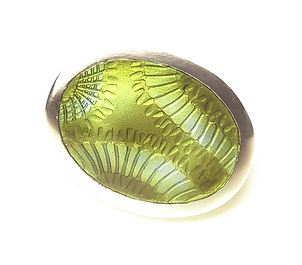

What is Basse-taille Enamelling?

Basse-Taille is the technique whereby transparent vitreous enamel is fired on top of a low relief textured design partially cut into the surface of the metal.

Engraving is usually used to create the decorative pattern but Etching or Chasing can also be used.

Basse-Taille enamelling produces gorgeous light and depth of colour in the finished design, a skilled enameller can vary the depth of the surface pattern to enhance the effect.

Guilloche (Engine Turning) can also be used to mechanically engrave an item prior to enamelling, this technique often seen on antiques or clock faces, shows fine, precise repetitive close spirals or linear decorative patterns visible under the transparent enamel.

Other Enamelling Techniques

- A brief explanation

Painting Enamel (Limoges Style)

Different colours of enamel are placed (hand painted) next to each other without a wire or a relief cut to separate them.

Image: Museum Piece

Sgraffito

Lines are drawn or a design is scratched through a layer of unfired enamel, exposing the fused enamel colour or the base metal underlying. Several layers of enamel can be scored then fired to produce the finished pattern.

Torch Fired

Where the flame of a Gas Torch is used for firing the enamel instead of a traditional enamelling kiln.

Wet or Liquid Enamel

Specialist liquid enamels are a different consistency to usual Vitreous enamel and they can bye used to create different finishes by being be applied with techniques such as dipping, pouring, splashing and dripping.

Enamelling Courses

Would you like to discover how enamelling could offer you design options for your work?

1,2 or 3 Day Enamelling Courses (Private Tuition)

-

Private one-to-one tuition

-

Tuition in the tutor's own Jewellery studio

You can bring some copper or silver samples of your work to enamel on if you would like to undertake a day of research with tutor guidance, subject to technical/time feasibility.

Interested?

Make a Course Enquiry

Make an Enquiry here >

-

Advise your details on the form provided.

-

At this stage this is just an enquiry with no obligation to book. We understand you may need more information.